Gas Tube Bundle Flow Conditioner

1. Preface

With the development of flowmeter technology and in depth study in the natural gas measuring technology, our company has a new understanding on interference by up-stream flow resistant part to the fluid state and influence to the measuring accuracy.In the natural gas flow measuring, the latest study both at home and abroad shows that orifice plate flowmeter,ultrasonic flowmeter and turbine flowmeter. But interference by commonly used equipment such as collecting gas pipe,separator and control valve to fluid state needs over 145D(D means internal diameter,the same bellow)straight pipe sections to be eliminated. By using the method of lengthening the straight pipe sections to eliminate the interference of fluid state caused by flow resistant parts, not only exists technical difficultly, but also covers larger area and needs high-investment. At present, flow conditioner used to eliminate the interference to shorten the length of straight pipe and improve the measurement accuracy at home and abroad. To meet the application requirements, our company has been developed 19 tube bundle type flow conditioner and plate type flow conditioner in line with standards.

2. Structure Features

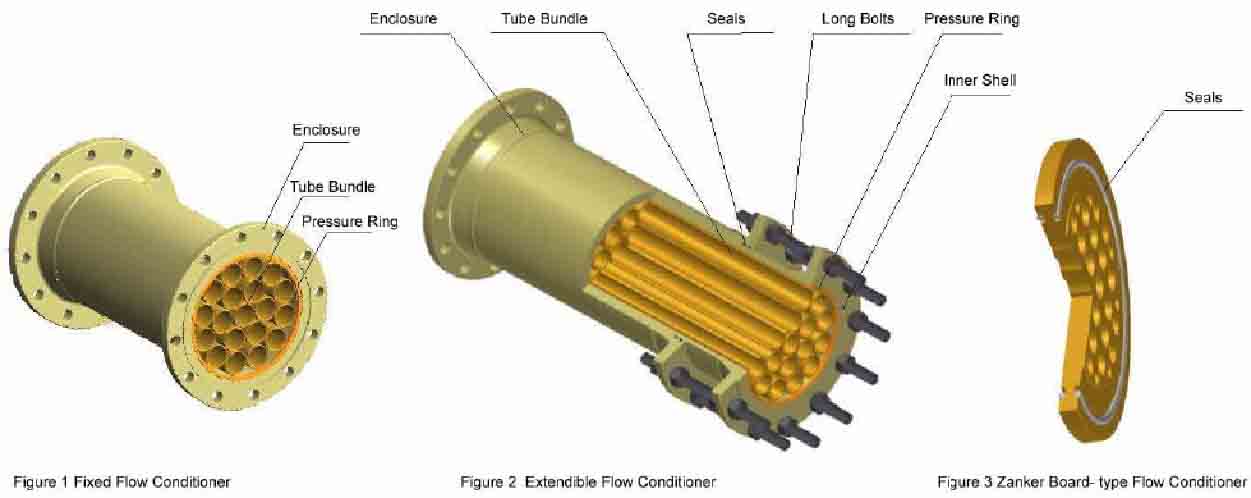

1. Fixed flow conditioner: Composed of the enclosure, flow conditioner tube bundle which is made up of 19 nosy of flow conditioning tubes and pressure ring (see figure 1), structure size is complied with national standards 19 tube bundle is molded one-time welding by using fixture positioning to ensure the accurate location of each flow conditioning tube and the performance of crators to symmetrical, orderly, smooth and firm.

2. Extendible flow conditioner: Composed of 19 nos of tube bundle flow conditioner and expansion pipe(See figure 2).This flow conditioner makes the pipeline disassemble easily, more suitable for the working condition of dirty medium and need to be often cleaned, and the situation required calibration regularly. Its expansion distance is 30 mm (Longer expansion distance can be designed upon request).

3. Board type flow conditioner: Composed of flow conditioning board with flow conditioning hole and seals in both (See figure 3), Its flow conditioning holes symmetrically distribute just like rays, its shape coincides with the fully developed velocity distribution.CNC boring machine processing to ensure the accurate position of each hole and roughness, so it has good flow conditioning performance.

3. Material of Main Parts

Name of Parts | Non-Sulphur resistant | Sulphur resistant |

Enclosure, Inner Shell | 20 | |

Flow Conditioning Tube, Flow Conditioning Board | Austenitic Stainless Steel 1Cr8Ni9Ti | |

Sealing Plate | Rubber 5080 | Fluorine rubber F370 |

Pressure Ring | Austenitic Stainless Steel 1Cr8Ni9Ti | |

Long Bolt | 45 (unless otherwise specified in contract) | |

4. Technical Specification

■ Medium: purified natural gas, sulf-natural gas, coal gas, air, steam and light oil etc.

■ Pressure class: PN1.6~16MPa

■ Nominal diameter and end-to-end dimension is shown in Table 1.

■ The inner diameter of the flow conditioner is the same with that of the measuring tube of flow meter, it should be provided by the flow meter manufacturers or customers.

5. Requirement of Installation

1.Flow conditioner should be installed between the flow meter and the first flow resistant part at up-stream.

2. The flange of flow conditioner is conformed to JB/T82-94 male and female facing flange, the flange between the flow conditioner and the up-stream measuring pipe is male flange, also can be other type upon request.